Brake actuator is an important part of tractor braking system, especially 550 series of tractor. This critical role is playing in the reliability and responsiveness of braking when employed in agricultural and industrial environments due to frequent deployment of these tractors since reliability and responsiveness of braking are vital for safety and operational efficiency.

So, if you are in need to understand, maintain or replace 550 tractor brake actuator then this guide is going to show you everything you need to know about. This article covers every detail from its functionality and common issues to step by step replacement instructions and tips on how to source high quality parts.

What is a Brake Actuator?

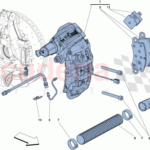

A brake actuator is a mechanical or hydraulic device that takes force or pressure and converts it mechanically to the force or pressure required to actuate the brake pads or shoes. It makes sure that brake pedal or brake lever causes an appropriate stopping power with the braking system.

The brake actuator in a 550 tractor is often part of a larger hydraulic braking system that also includes the master cylinder, brake lines and pads working in concert to produce a smooth and quick brake response.

The Brake Actuator in a 550 Tractor: How it Works.

The brake actuator operates by forcing the brake assembly when the operator presses the brake pedal. Here’s a simplified breakdown:

Hydraulic or Pneumatic Pressure: Pressure on the actuator comes from the braking system (in the case of hydraulic or pneumatic braking).

Force Conversion: This pressure is then acted on by the actuator, producing mechanical force.

Brake Engagement: The resistive force, which pushes brake pads against the rotor or drum, and produces friction slowing the tractor down is this.

The 550 tractor’s braking system is particularly robustly designed to be able to handle big load and rough terrain but with fine control.

Why is the Brake Actuator Important?

Safety: After all, a decent brake actuator ensures that in case of a tractor that can stop instantly, minimizing the chances of an accident.

Efficiency: Good brakes make precise work on slopes or in uneven terrain possible, thus enhancing productivity.

Durability: The brake actuator takes pressure off other parts, and evenly distributes braking force, reducing wear and tear of other parts.

550 Tractor Brake Actuators Common Issues

Brake actuators, like any other part of a mechanism, may be found to wear out with time. Here are some common issues and their symptoms:

1. Reduced Braking Power

Cause: Hydraulic fluid leaking or internal component leaking.

Symptom: Stopping the tractor takes more work.

2. Sticking Brakes

Cause: Actuator debris, dirt or corrosion inside the actuator.

Symptom: When the pedal is released, brakes are still engaged.

3. Fluid Leaks

Cause: Damaged brake lines, or cracked seals.

Symptom: Actuator or hydraulic fluid visible on ground or near actuator.

4. Uneven Braking

Cause: Something as simple as one out of alignment or one actuator that is out of alignment or just one actuator that is not working right.

Symptom: When braking the tractor pulls to the side.

5. Strange Noises

Cause: Internal components wore or were damaged.

Symptom: Braking noises that include grinding, squealing, or clicking.

550 Tractor Brake Actuator Maintenance

Maintaining your brake actuator properly can reduce the chances of it failing when doing so and prolong the life of your brake actuator. Follow these tips:

1. Regular Inspections

Please inspect the actuator for visible signs of wear, corrosion, or leaks.

Make sure all the connections are neat and free from dirt or debris.

2. Clean the Actuator

Dust, mud or debris that can build up on the actuator can prevent it from performing its intended function so be sure to remove this accumulated material.

3. Check Hydraulic Fluid Levels

Make sure the hydraulic fluid is up to the proper level, and free of contamination.

Replace the fluid according to the specification in the maintenance manual of the tractor.

4. Lubrication

Reduce friction and prevent corrosion of moving parts of the actuator.

5. Replace Worn Components

If you notice any wear, or damage, act quickly. Not repairing it delays further problems.

550 Tractor Brake Actuator Replacement

Depending on how bad the repair is, you may have to call up your tractor dealer to replace your brake actuators to get your tractor’s braking performance back.

Tools and Materials Needed

Replacement brake actuator (Replacement tractor 1st echelon unit 550 tractor type).

Wrenches and sockets.

Depending on your apparatus, hydraulic fluid (if applicable).

The gloves and the goggles.

Jack and stands (if needed).

Replacement Process in Step by Step

Prepare the Tractor

Put the tractor on a flat surface that you park it.

Make sure the parking brake is engaged, and the engine is off.

Access the Brake Actuator

Find the rear braking system brake actuator.

Take away any protective covers or panels.

Disconnect Hydraulic Lines

Pull out the hydraulic lines on the actuator but do so carefully. Put fluid that spills out into a container.

Remove the Old Actuator

Remove the bolts or fasteners attaching the actuator to the brake assembly.

Be careful as you remove the actuator to not smash surrounding components.

Install the New Actuator

Mount the new actuator such that it lines up (or ‘realigns’) with the mounting points.

Bolts securing it, and tightening them to the manufacturers torque specs.

Reconnect Hydraulic Lines

Hydraulic lines to the new actuator must be rebuilt, but should make sure to have tight and secure connection.

Bleed the Braking System

Remove any air bubbles in the hydraulic system bleeding it and checking that the pressure and responsiveness are okay.

Test the Brakes

Ensure the new actuator is working correctly by starting the tractor and pushing the brakes at low speed.

550 Tractor Brake Actuators – Where to Buy

1. Authorized Dealers

Replace with genuine replacement parts, check with tractor manufacturer or authorized dealers.

2. Online Retailers

Amazon: It has different types of brake actuators for various tractor models.

eBay: Great way to find both used and new components.

Tractor Supply Co.: A trusted source of modern equipment and bits.

3. Local Tractor Repair Shops

Brake actuators for the 550 tractor are many repair shops and can be ordered.

4. Specialty Websites

Tractor parts can be purchased at Websites such as Parts Warehouse and All States Ag Parts that sell brake actuator.

550 Tractor Brake Actuator Replacement Cost

Parts Cost

Genuine brake actuators: $150–$400.

Aftermarket options: $100–$300.

Labor Cost

Professional replacement: $150–$300 per hour (depending on location, complexity).

Total Cost

DIY replacement: $100–$400 (part only).

Professional service: $250–$600 (including labor).

Brake Actuator Trouble Shooting Tips

Check for Leaks

Check hydraulic lines and seals for fluid leakage.

Listen for Noises

Worn components will cause grinding or squealing.

Test Brake Response

Actuator and/or hydraulic problems will result in delayed or weak brake response.

Look at how the Actuator moves.

Make sure the actuator moves smoothly and doesn’t ‘stick’ or ‘bind.’

550 Tractor Brake Actuators FAQS

1. How long is a brake actuator going to last?

A brake actuator can last 5–10 years or more with proper maintenance but usage and environmental conditions will determine how long the lifetime is.

2. Am I able to use aftermarket brake actuator?

That is yes but make sure that the 550 tractor model is suitable and also be of quality.

3. I want to know if my actuator is going bad.

It may show up as poor braking ability, fluid leaks or strange noises when braking.

4. Is professional replacement required?

If you’re not familiar on brake systems, it’s recommended that you have them repaired professionally through DIY replacement.

Conclusion: How to keep your 550 Tractor running smoothly

The 550 tractor brake actuator is a vital part of making agricultural and industrial operations both safe and efficient. One way to eliminate problems and increase tractor performance is to understand the function of the tractor, keep it well maintained and when it is time to replace it.

This guide will give you the skill and the resources no matter what your experience level is with your 550 tractor: whether a novice or a veteran mechanic. Braking has to start out safe and reliable and is based on starting out with the right care and quality replacement parts.

Focus Keyphrase:550 tractor brake actuator

Meta Description:Learn about 550 tractor brake actuators! Explore functionality, maintenance, replacement tips, and where to buy quality parts to ensure reliable performance.